Lean Operations For Unstoppable Growth has proven to be an effective model for managing teams in some of the most demanding industries, such as software development, manufacturing, construction, etc. With its holistic approach encompassing five core principles – value identification, value stream mapping, flow creation, pull system establishment, and relentless pursuit of continuous improvement – Lean thinking, when executed effectively, can yield a remarkable and far-reaching impact.

To successfully apply the Lean Operations For Unstoppable Growth methodology and build an organization where cultural changes are welcomed, it is vital to understand the foundation principles of Lean management and how to implement them properly to achieve an effective organizational transformation.

This article will discuss the 5 Lean management principles, highlight their unique traits, and provide valuable tips for a successful Lean transformation journey.

What Are the 5 Lean Management Principles?

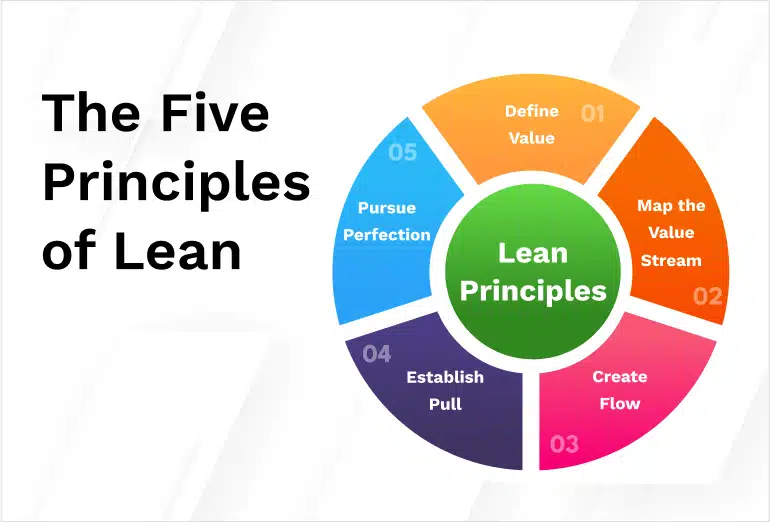

The five principles of building an efficient Lean management process include identifying value, mapping how value is created, creating a flow, establishing a pull system, and always seeking improvement.

Lean is about changing an organization’s culture toward focusing on the people who do the work and continuously improving the way work is done. To better understand each of the 5 Lean management principles and succeed in your Lean transformation, let’s look closely at and recognize the core of each principle.

5 Lean Operations For Unstoppable Growth

1. Identifying Value

To lay the foundations of a Lean process, you must identify the team’s work value and separate the value-adding activities from waste activities. Everyone must actively participate in this collaborative activity to ensure collective understanding and alignment.

To understand value, consider the end product of your efforts and what your customer gets from it. By definition, value is everything that your customer is paying you for. However, some teams (e.g., quality assurance teams) do not produce direct value for the company’s customers but enhance the overall value that the organization delivers.

In this case, the customer is your company. For example, the value of a quality assurance team’s work is the number of bugs they catch, which ensures that the whole company will deliver a valuable product to the end user.

Lean identifies seven types of waste. Waste activities can be categorized as pure and necessary. The main difference is that some waste activities are required to support the value-adding ones, while pure waste activities only harm the Lean workflow.

Quality assurance is the brightest example of a necessary waste regarding software development. It doesn’t generate direct value for the end customer, but it ensures the development process’s value is preserved.

2. Mapping the Value Stream

The second of the five principles of Lean is about the value stream. That’s why, after you’ve identified the value that your team creates, it is essential to visualize its path to the customer. In Lean management, this is usually done with the help of Kanban boards.

The Kanban board is a tool for mapping every step of your process and, therefore, visualizing your team’s value stream. Developed also as part of the Toyota production system, the basic Kanban board is a vertical flat surface divided by columns for the three primary states of any assignment:

Although visualizing your workflow this way is a good start, you should consider mapping your process more precisely by including the steps that compose each stage. For example, a “Requested” stage may have two steps – order received and ready to start. Usually, “In progress” consists of the most significant number of steps.

Depending on your unique scenario, there can be infinite Kanban board examples. In the software development context, you typically have steps like tech design, development, testing, and at least a few review stages.

When mapping your value stream for the first time, focus on value-adding steps to create a Lean Operations for Unstoppable Growth process. Be sure to correct it occasionally as your process evolves.

3. Creating a Flow

In the world of Lean, flow is a key concept. Since any waiting is a waste, when creating a flow of value, your goal is to ensure smooth delivery from the second you receive an order to when you deliver it to the customer.

A significant barrier to creating a smooth flow is the bottlenecks in your process. As a manager, you should watch how work progresses through your workflow. Pay extra attention to areas where work tends to get stuck. This way, you can dig deeper and figure out why it happens in the first place. Bottlenecks may be caused by a lack of capacity at a particular stage, waiting on external stakeholders, etc.

The review stages are among the most common bottlenecks in any process because, most of the time, the people reviewing work items are fewer than those who submit them, and often, the reviewers become overwhelmed.

Eliminating bottlenecks in your process is crucial for creating a smooth and Lean process flow. If you can’t alleviate bottlenecks, at least protect existing ones from getting clogged.

A simple way to do it is to limit the work your team can have in progress simultaneously. With this in mind, discuss the topic with your team and agree on acceptable WIP limits to help them achieve maximum efficiency.

Ensure that they understand how harmful switching context can be to their productivity and experiment with different limits until you achieve multitasking efficiency and a smooth flow of tasks.

4. Establishing Pull

Once you have created a smooth workflow, the fourth Lean principle urges you to establish a pull system. The idea is simple: Start new work only when there is a demand for it, and your team has spare capacity. Your goal should be to create the value your customers need and avoid creating anything in surplus, e.g., overproduction.

To visualize it clearly, let’s compare how assignments are processed in a pull system to the typical push model.

Simply put, team managers or leaders create and assign work items to team members in a push system. In other words, work is pushed onto the people executing it.

By contrast, the work that needs to be processed in a pull system is stored in a queue. A team member currently not working on anything will go to the queue and take the item with the highest priority they can work on. The people doing the work pull the assignments and start processing them.

As a Lean Operations for Unstoppable Growth organization, your goal is to deliver value to your customers efficiently. One way to ensure that is by focusing on two key flow metrics: cycle time and throughput.

The cycle time of your tasks is when your team is actively working towards their completion, while throughput is the number of functions you finish in a predefined time frame.

As a leader looking to implement the 5 Lean principles and practices, you should aim for shorter cycle times, resulting in increased team throughput.

5. Seeking Constant Improvement

This Lean principle is closely related to continuous improvement, an integral part of Lean management.

Your goal is constantly improve every process in your team by enhancing the activities that generate the most value for your customer while removing as many waste activities as possible.

Continuous improvement can be achieved with methods such as Plan-Do-Check-Act, known as PDCA, but it is more of a mindset that you have to inspire in your team. To help your team achieve continuous improvement, you should consider how you lead them.

Suppose you are among the traditional managers who prefer to control every single activity and micromanage even the execution of small tasks. In that case, you may have to change your style and implement a shared leadership model.

Continuous improvement can only blossom if every person on your team embraces ownership. This can prove difficult when they can’t handle the most minor issues independently. Place more trust in their expertise and increase their independence in time according to their performance.

A good start would be to incorporate the Lean/Agile practice of the daily stand-up meeting where you can keep them accountable. During the short meeting, every person explained what they’d done the previous day, what they intended to do today, and if there were any obstacles.

In addition to applying each of the five principles of Lean, you’ll also have the responsibility to enlighten your team and help them understand why each one is vital, with the goal of embracing them as a culture.

3 Good Practices to Implement Lean Successfully

To ensure a successful implementation of Lean management processes, there are three fundamental prerequisites you need to address: setting explicit objectives, cultivating a lean mindset, and starting with small steps.

1. Set Clear Goals

First, you need to know your end goal and communicate that with everybody on your team. What are you trying to achieve by implementing the Lean process within your company?

Is it optimizing your workflow so you can have faster product deliveries? Are you trying to increase your overall business profitability as a result? Or perhaps you want to ensure business and organizational agility.

Whatever your goal, it needs to be clearly defined. This way, you can share a path to Lean Operations For Unstoppable Growth to achieve it, motivate people to take the journey with you, and assist them by removing any obstacles that appear on your way to process perfection.

2. Establish a Lean Mindset

It is essential that you lead the change, not manage it. Once you know the implementation’s outcome, you need to integrate the Lean mindset within your team.

Dealing with the human factor and getting everybody on board might be a significant challenge. That’s why, to get started, you need to explain Lean to your team members and ensure they understand its benefits from both an organizational and personal perspective.

The Lean process is about delivering superior customer value by eliminating waste and cultivating an environment of shared leadership where your team members receive more responsibilities and seek continuous improvement. Once your colleagues understand that, they will more likely embrace the change.

3. Start Small and Find a Change Agent

A good practice is to start with a single team and later spread the Lean practices across departments, eventually transforming your whole company into a Lean organization.

If you are working at an enterprise level, you can form a pilot group of members of different teams so they can serve as change agents after they return to their original teammates.

For example, if you have a large RnD department comprising multiple teams working independently, you should ask for volunteers from each team.

A good way to ensure they will be fitting change agents is to select only enthusiastic people who are influential in their teams (e.g., senior members, informal leaders, etc.). Once you set a strong foundation, introduce the five principles of Lean management.

Ready to unlock your entrepreneurial potential with Lean operations? Contact us today to learn how our tailored training programs can equip you with the tools and strategies to drive sustainable growth and efficiency. Let’s work together to turn your business into a success story!

Criar Conta Pessoal

Your article helped me a lot, is there any more related content? Thanks!

Create A Free Account

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.